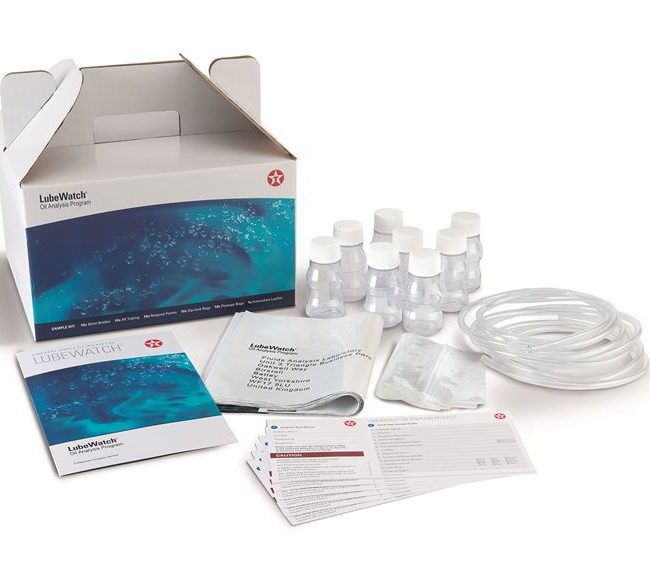

LubeWatch maintenance management system is a diagnostic,

preventive maintenance tool that uses oil analysis to monitor

and evaluate lubricant and equipment condition in all types of

mobile and industrial applications.

Lubricants are the “lifeblood” of machines and equipment. Routine testing and analysis

can show you how the condition of the lubricant can affect equipment performance and

reliability. Imagine being able to see exactly what’s happening inside an engine, a gearbox

or hydraulic system. Problems can be found before they become engine failures and less

unscheduled downtime means increased production and profitability.

What the LubeWatch Maintenance Manage System Can Do For You

• Identify minor problems before they become major failures

by monitoring trends in wear and contamination to help prevent

catastrophic failure

• Extend drain intervals by performing oil changes when the

condition of the oil requires it helps reduce unnecessary labor costs

• Extend equipment life by monitoring system cleanliness helps

reduce repair and replacement costs and helps enable you to keep

equipment longer

• Maximize asset reliability by scheduling downtime according

to your schedule helps eliminate unforeseen decreased production

High Quality Testing

The LubeWatch Maintenance Management System utilizes an independent

ISO 17025 accredited laboratory. This is the highest level of quality attainable by

a testing laboratory which is backed by the most stringent accrediting body in the

industry. You can be confident that the results you receive are accurate, repeatable

and traceable to a recognized industry standard and that the oil analysis program

is supported by a documented quality system.

Innovative Data Management Solutions

LubeWatch test results are accessible through HORIZON,® a web-based software

application serviced by POLARIS Laboratories®, that will show you how to get the

most from your testing results and analysis. After the sample processing is complete,

the test results are FREE and available within a 24-hour turnaround in 90 percent of

cases. Management reports are available that allow you to use the data to affect

positive change in your daily maintenance practices by:

• Keeping sampling schedules on track

• Identifying bottlenecks in turnaround time

• Influencing future purchasing decisions

Test Results On the Go

View test results and maintenance recommendations

on the HORIZON app when you are in the field or on the

maintenance floor. Alerts notify you when new results

are ready. Customize alerts by fluid type and severity.

Download the free app from Google Play for Android

devices and the App Store for iOS devices.

C1 LUBRICATION — BASIC

Viscosity @ 40°C or 100°C

(mod. ASTM D445)

Trace Elements & Additives

(mod. ASTM D5185)

% Water (Crackle Test)a

C2 DIESEL CRANKCASE

Viscosity @ 100°C (mod. ASTM D445)

Trace Elements & Additives

(mod. ASTM D5185)

% Water (Crackle Test)a

Glycol (ASTM D2982)

Fuel Dilution (ASTM D7593)

Fuel Soot by Wilks Soot Meter

Base Number (mod. ASTM D4739)

C3 NATURAL GAS

Viscosity @ 100°C (mod. ASTM D445)

Trace Elements & Additives

(mod. ASTM D5185)

% Water by Karl Fischer (mod. ASTM D6304C)a

Oxidation (ASTM E2412)

Nitration (ASTM E2412)

Acid Number (mod. ASTM D664)

C4 INDUSTRIAL OILS

Viscosity @ 40°C (mod. ASTM D445)

Trace Elements & Additives

(mod. ASTM D5185)

% Water by Karl Fischer

(mod. ASTM D6304C)a

Oxidation (ASTM E2412)

Nitration (ASTM E2412)

Acid Number (mod. ASTM D664)

C4 PC: Includes all tests from C4 plus

Particle Count (mod. ISO 11500)

C5 METAL WORKING FLUIDS

Viscosity @ 40°C (mod. ASTM D445)

Trace Elements & Additives

(mod. ASTM D5185)

% Water by Karl Fisher

(mod. ASTM D6304C)a

Chlorine (ASTM D5384)

Sulfur (ASTM D4951)

% Fat (ASTM E2412)

C6 TURBINE OILS

Viscosity @ 40°C (mod. ASTM D445)

Trace Elements & Additives

(mod ASTM D5185)

% Water by Karl Fisher (mod. ASTM D6304C)a

Oxidation (ASTM E2412)

Particle Count (mod. ISO 11500)

Water Separability (ASTM D1401)

Oxidation by Rotary Pressure Vessel

(ASTM D2272